As a special member in nx-family, nxSpector has been especially designed for sorting/inspecting jobs with its 3-D information. The sorting/inspecting task is completed via comparing the live 3-D data with the stored template or form. The template or form is prepared by users and stored with the sensor.

nxSpector is associated with a device utility program for configuring, setting, and loading data and parameters to/from nxSpector. With the help of the software, users can create template with existing parts, define valid data segments, and build part classifiers.

nxSpector works with external trigger signals or host computer commands. Upon the arrival of an object, a proximity device triggers nxSpector. Then nxSpector acquires data, completes verification, and outputs inspection results to a 16-element buffer. Users can easily transfer the resultant data from output buffers to control activators.

Features:

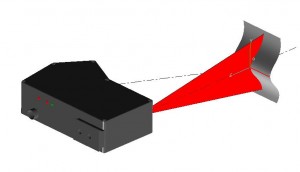

- Sophisticated Laser Technology for Non-contact Sensing and Measuring with self-adaptive capability;

- Advanced Digital Imaging Technology with Real-time Data Acquisition and Processing;

- Embedded Digital Signal Processor (DSP) for Dedicated 3-D Coordinate Computing from Real-time Image Data;

- Auto-learn & Auto-track Functions for Dynamically Tracking Object Conditions;

- Plug-n-Play Industry-standard USB Interface Ready for Networking in Multiple-task Measurement Environments;

- Built-in External Trigger and Software Trigger Modes for Synchronization.

- Low-power & Sleep Modes for Less Power Consumption When Standby.

Typical Applications:

1. On-line inspection and sorting objects (not black or transparent);

2. 100% auto body inspection: body-in-white or other subassembly;